I'm tired of washing my prints in the kitchen sink. It's just too small and i can't leave it alone because the prints sink to the bottom, block the tap; the sink fills and my kitchen starts to flood. And woe betide me if i decide to print some 12 x 16 paper!

Suffering from the same problem? Lo, read on to see how you can make an inexpensive (really, it cost me about £20 in total) print washer.

First off, materials. Here's what you will need:

- Plastic storage container (any size you like),

- 2 x 2 metre lengths of plastic waste pipe (any diameter you fancy),

- Some 90 degree joints that will fit your pipe (get about 8),

- Hosing/tubing (approximately 2 metres),

- Drill

- Saw

- sandpaper

- Glue gun/silicon sealant

Step 1

Grab your storage box (mine cost about £11 and can easily fit in 12 x 16 prints) and drill 2 holes roughly the same diameter as your waste pipe just an inch or so below the top of the container towards the left and right hand side. To do this you may have to use a hole cutter (its like a round saw which you mount on your drill). Unfortunately i didn't have a hole cutter the right size so i drilled my holes bigger.

Step 2

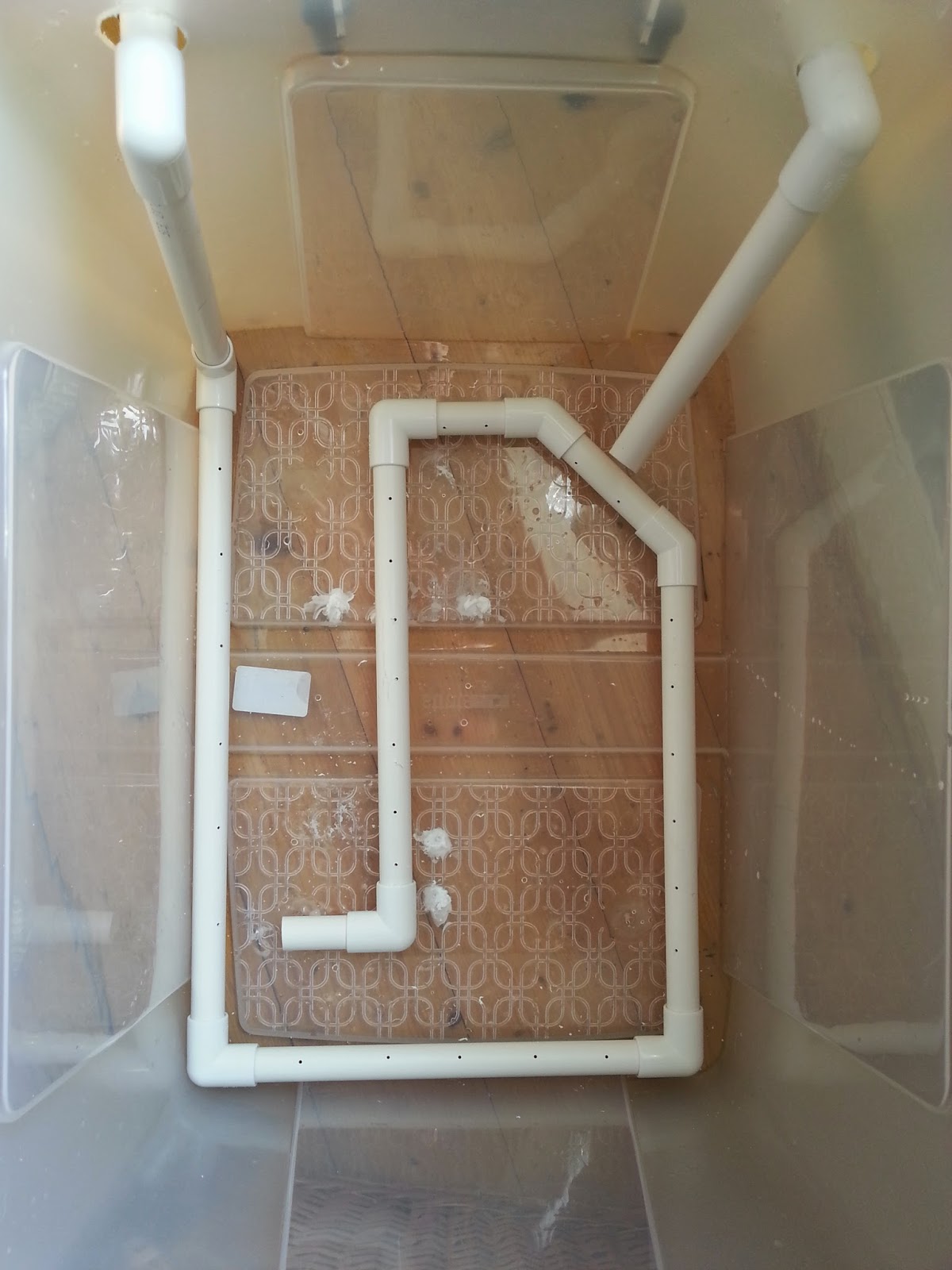

Cut a small section off your pipe and feed it through the hole on your nearest side, push on a 90 degree joint (making sure you sandpaper down the edge you have just sawed) and then attach a vertical section of pipe which extends just shy of the base of the container.

Step3

Now do exactly the same with the other hole, but this time saw the tip of the pipe at about 45 degrees to get a spout.

Step4

Now go back to your first length of piping and measure along the base of your container then cut a length of pipe just a little less than the length you measured. Smooth off the sawed edges of the pipe with sandpaper and attach it to the pipe you already have.

At this stage i tried attaching a length of hose to cover the base of the container but it didn't quite work out. Instead, keep attaching lengths of pipe and joints until you get good all round coverage along the base of the container. You dont need to cap off the last piece, this will serve as an outlet for the water which flows through the system.

|

| Not like this! |

|

| Like this! |

Now take your drill and (using a small drill bit) drill holes every 2 inches or so apart along the entire length of the tubing which is sat in the base of the container.

Step 6

Retreat to the bathroom (or wherever you're planning on setting up this washer) and check out your taps. If you have the kind of taps you can just push hosing onto then all well and good, connect a length of hosing from the first piece of piping onto your taps. This will mean water will flow in, down the vertical length and through the loop you have made in the base of your tub; flowing out from the last length to be picked up by the second vertical pipe which will act as a siphon.

Now, my taps are mixers which means i cant push any hosing over them. But, i can unscrew the shower and push the hosing onto the screw attachment (yay).

|

| Like so! |

Attach a length of hosing onto the second pipe and point it plugwards. Turn your tap on and you should see water spurting out through the holes you have drilled and the container will start to fill.

You should see some good agitation in the water as the container starts to fill (which is exciting isn't it).

Step 7

Now, remember i drilled my holes for the pipe inlets bigger than the pipe? I'm going to need to seal that up. Take some plastic (e.g. from a bottle) and cut out a square which more than covers the holes you cut. Cut out a hole as close to the diameter of the pipe as possible and use a glue gun or some silicon to attach the plastic to the container, with the pipe running through it. If you don't do this then the water will just leak out of the holes you made and the second pipe won't act as a siphon.

Step 8

Once that's all done you will have to ma the tap for a while to get the right flow. Keep adjusting the amount of water coming out of the tap until what's going in matches what's heading out of the second pipe. It helps to drill a small hole in the top of the second pipe and stick a match in it. The match can be used to increase and decrease outflow. Preferably you don't want the water to flow out over the top of the container.

Step 9

The final step is to make something to support your prints. It should be easy enough to source some acrylic or perspex sheets, cut them to size, attach them to some rods and put that in the tank. As i already have a Paterson drying rack, however, i decided to use that. These are cheap and come up relatively often on Ebay.

And that's about it. It's not the most hi-tech thing ever created but it's cheap and cheerful and should wash your prints sufficiently (i can't guarantee that of course). It's certainly better than flooding my kitchen!

The way it works is that the water flows in and goes through the loop at the base. The drill holes allow water to spurt out which agitates the water, causing motion around the prints. The water picks up the fixer and, as fixer-laden water is denser than clean water, it sinks to the bottom of the container. It should then be picked up by the outflow pipe and siphoned out down the drain. Science! I haven't technically finished mine yet as i haven't sealed up the original drill holes so my siphon isn't really working but it will. IT WILL I SAY! Just for fun, here's a super-entertaining video of mine showing this mega-agitating washer in action (caution: may cause your mind to blow, it's that exciting):

So that's it. A print washer for those of us on a budget. Those hundreds of pounds you have now just saved can go on something better like film, paper, chemicals or (woe of woes) rent! As always keep printing and ill see you again soon.